Who we are

Torque Converter Technologies has been in business since 1996, providing expert service in aftermarket torque converters and transmission components. The company proprietor, Nazir and his team of 15-strong converter and transmission experts provide a highly specialised service for drivers throughout Australia who are looking to improve their vehicle’s power delivery.

Our key staff members have worked in the industry since the 1980’s, each clocking up their multiple decades of experience in the field.

what we have to offer

Our standard remanufactured torque converter range also includes performance high stall, heavy duty industrial and units specially developed for commercial, 4WD and off road applications. A wide range of modified and upgraded converters are available to suit Ford, Chrysler, GM, Toyota, Subaru, Mercedes, Land Rover and many more.

Common Questions

Most automotive enthusiasts know that when they run an automatic transmission they must run a torque converter. They may even consider the converter part of the trans, although the two can be and often are purchased separately. Automotive enthusiasts also know they can see a performance gain in many cases when they switch to a higher stall speed torque converter.

However, even hardcore enthusiasts often have no idea how a torque converter actually works. After all, it arrives all sealed up – you can’t open it, inspect it, modify it or maintain it, you just choose one, install it and hope you’ve made the right choice.

Fortunately, torque converters don’t have to be mysterious. We’ll explain what they do, how they do it and why you might want to change yours.

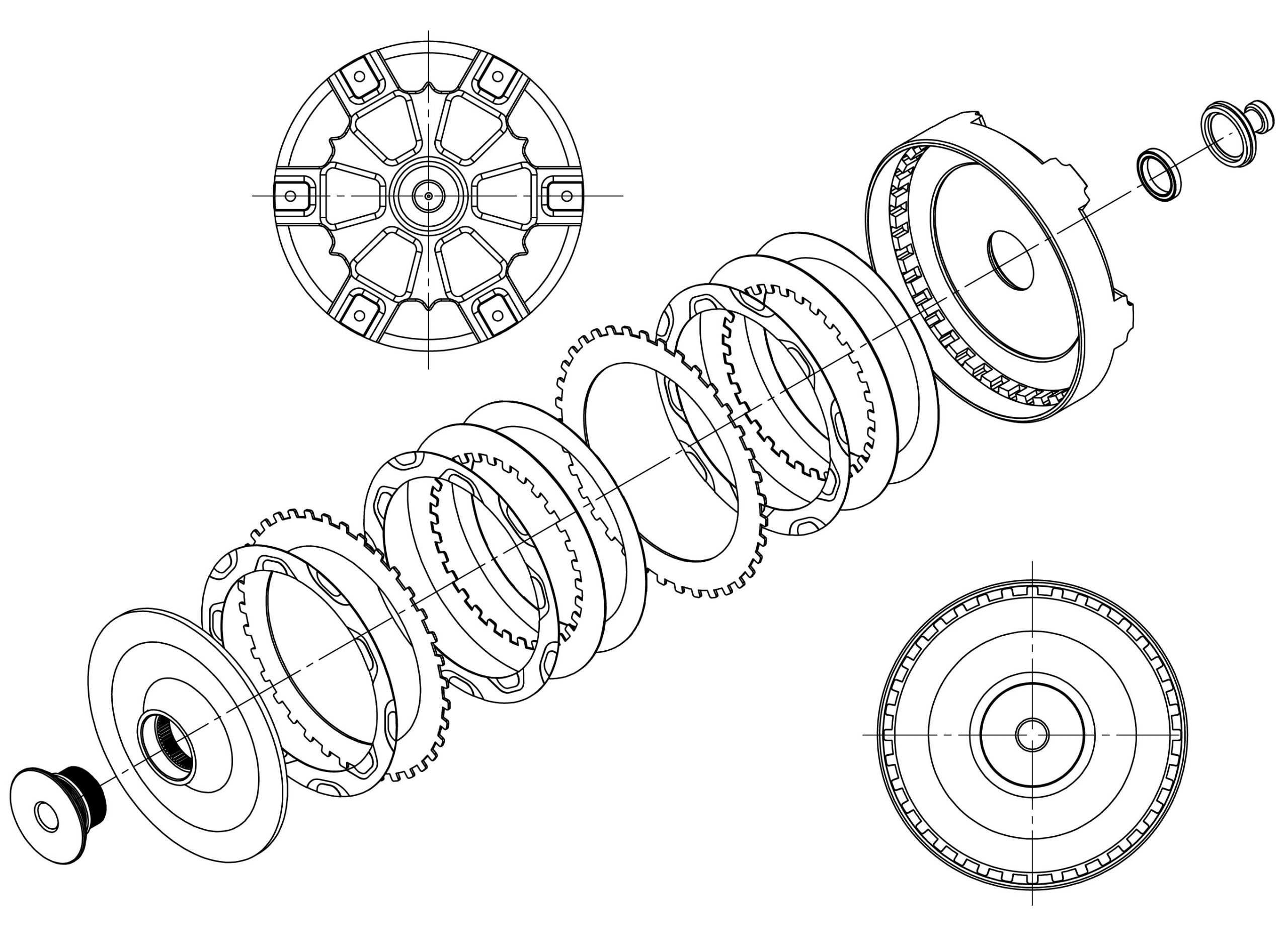

At the most basic level, a torque converter connects the engine to the automatic transmission, much like a clutch connects an engine to the manual transmission. The converter housing bolts onto the motor’s flexplate (sometimes called the flywheel), and the housing spins right along with the motor’s crankshaft. On the output side, the torque converter’s turbine is attached to the transmission’s input shaft. Inside the torque converter is a stator assembly, the job of which is to redirect the trans fluid flow. This results in torque multiplication, which allows a converter to provide better low speed acceleration.

Most torque converters today will multiply torque by a ratio of at least 2-to-1 – eg. if an engine is making 250lbs/ft, a converter will transfer 500lbs/ft of torque to the transmission. This improves your car or truck’s acceleration capability substantially. Aeronautical Scientist defines a torque converter as “a device for changing the torque speed or mechanical advantage between an input shaft and an output shaft”. The goal for automotive enthusiasts and racers is to gain a mechanical advantage.

The torque converter also serves another extremely important function in a car or truck. A vehicle’s engine must be able to connect and disconnect from the differential, so the vehicle can stop moving (ie. turning the drive wheels) while the engine is still running and the transmission is in gear. In the case of an automatic transmission, it is the torque converter that performs this connect/disconnect function (again, like a clutch for a manual transmission). By slipping internally, the torque converter allows a car’s engine to idle while it’s in gear.

Stall speed is commonly referred to as the RPM speed at which the converter will hold back or limit the engine when the automatic transmission is prohibited. By not allowing the engine further RPM gain, the increase in engine RPM ‘stalls’, or ceases to increase.

The important thing for enthusiasts to remember is that ‘stall speed’ is a direct relationship between the engine’s ability to produce power and the torque converter’s ability to hold the RPM back. Changes to either the engine’s power output and/or the converter will change the balance and in turn will change the ‘stall speed’. The RPM at which stall occurs within a converter is a function of engine peak torque. This is why the same high stall converter will not ‘stall’ the same when interchanged between two different engines, producing vastly different power outputs.

Lockup converters contain another part; a torque converter clutch. When the clutch engages, it allows the converter to lock the engine to the transmission input shaft, proving a direct 1:1 connection from the motor to the transmission.

In many ways it comes down to fuel economy. Lockup torque converters have become popular since auto makers have been stuck in a sort of catch-22 situation. Car buyers overwhelmingly prefer automatic transmissions, but automatic transmissions are not as fuel efficient to a vehicle as a manual transmission, and car makers must meet average government mandated fuel economy targets.

Overdrive transmissions have been one step along the path toward increased fuel efficiency from an automatic transmission equipped car. Overdrive transmissions allow the motor to spin at a lower RPM during cruising speeds. A higher final drive ratio (numerically lower does the same thing. However, when the engine spins more slowly, it creates more slippage within the torque converter and more slippage creates more heat. Heat within the torque converter reduces fuel economy and can harm both the torque converter and the transmission. The solution is to allow the converter to lock up at a 1:1 ratio. Lockup eliminates the slippage, which reduces heat and improves fuel economy.

If your car has been modified to enhance performance, you’ll probably need a converter with a higher stall speed. Most stock converters have a stall speed in the 1500-1800 RPM range. When you make performance upgrades to your engine, you generally shift the engine’s torque curve upward into a higher RPM range. Therefore you need a converter with a higher stall speed, so that you can launch the car in the “fat” or proper part of the engine’s power band.

If the stall speed isn’t enough, the car won’t be making the power when you launch, and you’ll bog the car off the line. If your car’s set up is really mismatched, the motor may even want to stall whenever you attempt to shift the gear at idle. So, a higher-stall converter will improve acceleration by allowing the car to launch at a RPM where it’s making its best power.

When selecting a converter without having an accurate and precise engine peak torque rating it is better to conservatively estimate the engine torque rather than overestimating it. Generally speaking, the desired stall speed of a converter should be around 500-700 RPM below the engine RPM at peak torque. This allows a margin for application of the torque reserve on takeoff.

Obviously you don’t want to launch the car at an RPM that is past your car’s peak power output. There is no point in bypassing the engine’s powerband. You also have to consider the car’s weight, engine size, engine component combination, power output, intended use, etc. when deciding which torque to use. Some converters are designed for high revving lightweight race cars, and some are designed for heavy cars that make a lot of low RPM torque, and there are converters designed for virtually everything in between. The key is to match the converter to the motor and the entire vehicle in question.

This is where technical support staff can help. Be sure to choose a good converter shop to purchase your high stall converter. The knowledge and experience of the tech people will mean the difference between purchasing the right converter that is going to work for you or a converter that you’ll constantly be having problems with. Technical staff will ask you questions about your combination, including things like where your engine makes its power, cam specifications, your vehicle weight and so forth, in order to help find the right converter for your overall combination.

You don’t want to get a higher staff speed than you need. That’s because high stall speeds create more slippage, which in turn generates more heat, which is hard on the converter and transmission. If you are going to run a converter with a higher than stock stall speed, you’ll want to install a transmission cooler to extend the lifetime of your components.

Amazingly enough, 85% of transmission failures are due to excessive heat. Higher stall speed converters also generally are not available with a lockup clutch. Again this means more slippage, more heat and less fuel economy, but the trade-off may be more than worthwhile for high torque applications, since a higher stall speed can subsequently improve a vehicle’s responsiveness.

Most performance engines are modified to produce additional horsepower and torque. The engine’s torque curve is normally raised to much high RPM ranges than stock before they begin to produce real power. The higher stall speed converters allow the engine RPM to enter the bottom range of the power curve and provide the optimum acceleration of the vehicle.

More stall speed is only good if your engine’s torque curve matches it. Too much stall speed is as bad as using too little. Increasing stall speed increases heat in the transmission. Excessive unusable stall speed is therefore detrimental.

He may have an engine that incapable of providing 2800 RPM stall speed.

It could be that the engine produces less actual torque than what he estimates for the engine. It could be due to camshaft specs, the engine is set up to produce optimum power for a much higher RPM and is producing very little torque in the 2500-300 RPM range.

Many people attempt to check the stall speed by holding the brake and stepping on the gas with the car in gear. This usually will not produce the true stall speed, as the brakes will not hold the engine and the tyres will start to spin first.

The best indication of the true stall speed is to launch the car at wide-open throttle and note the engine RPM. Stall speed is very difficult to determine unless your car’s transmission is equipped with a transmission brake to lock your drive train.

Testing stall speed by holding the wheel brakes and running the engine against the locked brakes will usually result in wheel rotation before true stall speed is reached. The engine simply overpowers the ability of the brakes to hold the car. When rotation starts you are no longer at stall. For this reason people talk about brake stall which is not a true stall. As mentioned earlier the alternative method of measurement is to launch the car at wide-open throttle and observe the engine RPM reached at launch. This is called flash stall.

The camshaft and converter are more closely tied than any other components in the car. If you chose a cam that produces power at higher RPM ranges, you must have a converter that coincides with that range.

Engine output is what really determines stall speed for a given converter. This is particularly true when changing camshafts, heads, carburetor, installing turbochargers, etc. All these will affect the stall speed of the converter. If you increase the available power output of your engine, the converter stall speed will be higher. This might be nowhere near the optimum stall speed for the engine configuration, to the point where the overall performance may not only remain unchanged, but could actually suffer.

This is where a lot of enthusiasts get caught out. They install a high stall converter, say a 2200 RPM stall and then over time continue to modify their engine to produce more horsepower and torque, forgetting that their 2200 RPM converter is no long suitably matched to the engine’s higher power output.

While stall speed is very important, it is by no means the only consideration when selecting a high stall converter. Torque multiplication at launch and high-end efficiency are equally important. Stall speed can be attained in many ways that hurt the converter performance in other areas. Stall speed can be obtained at the expense of looseness at low speeds and loss of performance at higher speeds after launch. It’s best to have a converter that produces the right stall without sacrificing performance.

An engine that would work well with this stall speed would be best described as a car with an aftermarket inlet manifold, a carburetor change and exhaust headers. For higher horsepower applications and for all out race vehicles, specialised custom high stall converters above 4500 RPM work best. For these applications however, it’s always best to consult the tech staff at your local converter shop, who will help you choose the right converter for you.

No. A higher stall speed converter is simply less efficient at RPMs below its intended stall speed. It will act quite normally for everyday street use.

Normal driving is not affected by stall speed up to approximately 3000 RPM, particularly with a well built converter. A car will begin to roll normally when a higher stall speed converter is used. Quick acceleration will be favorably influenced by stall speed. A very high stall speed, above 3000 RPM, would not be satisfactory for everyday street use.

Accelerator stamps each specific converter with an alphanumerical code, which tells us what components have been used to build the converter and for what application it was intended.

Although a relatively young company, the owners and technicians reflect many years of hard earned experience. All of the team at Accelerator High Stall Converters have unique backgrounds which ave put a premium on performance. The expertise and racing experience of the team allows each person to be active in developing and supplying products, demanded by performance and racing enthusiasts. This experience is focused to bring you the customer the best products the industry can offer. The technical department consists of professionals in the transmission, converter and performance/racing industries. They are able to advise you on the right stall speed converter for your application.